Project Description

| Type | CCS-1011 (Standard) CCS-1012 (Small) |

|---|---|

| IP Code | IP67 (Limit Switch) |

| Number of Contacts | 1NO+1NC |

| Capacity of Contacts | AC 125~250V 10A; DC 30V 5A; DC 125V 0.5A |

| Detecting Force | 9.8N~14.7N (End of Detection Flap) |

| Reset Type | Auto Reset |

| Working Temp. | -20~60°C |

| Working Humidity | ≤80% |

| Weight | 10kgs |

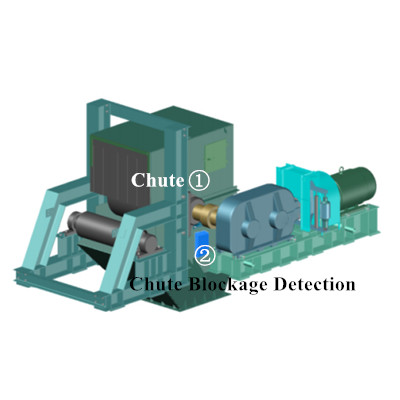

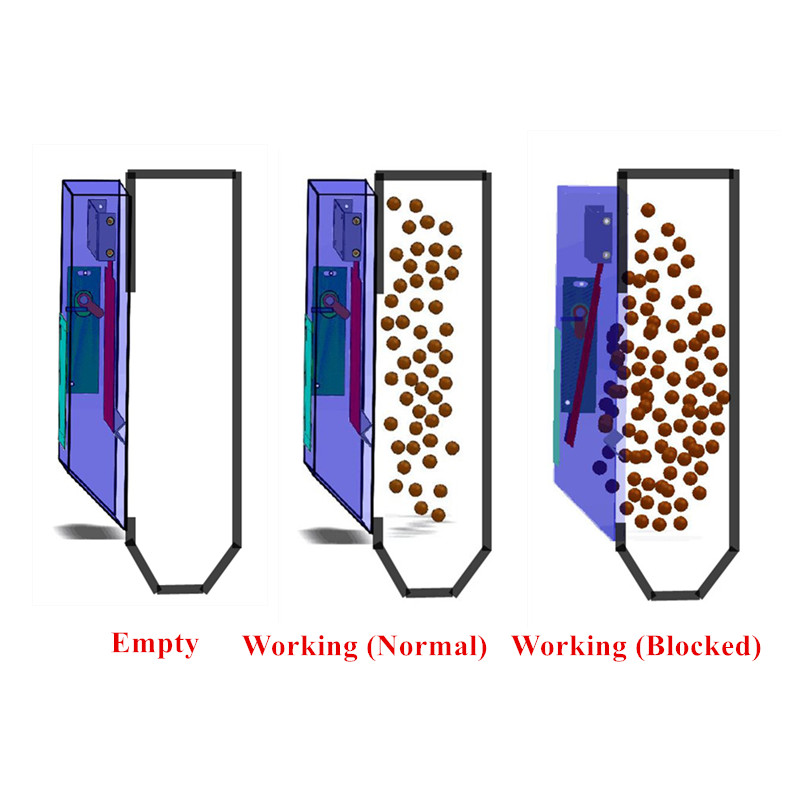

Chute blockage detector is widely used for monitoring material jamming in chute. If material jammed in chute, this switch will be activated and may stop the transport system in time to avoid machine broken or process failure. Conveyor receiving point is the easiest damage part on the belt, especially in the case of equipped the loading hopper/chute. Such incidents might be caused by the certain reasons and in some circumstances as follows:

- Too big size bulk material is fed into the hopper

- Materials stick with high moisture

- Downstream conveyor belt slipping

If materials blockage or build-up in the chute, Belt must stop immediately; otherwise it could cause a serious accident, resulting in the failure of production process, the belt tearing or even a fire accident. Chute blockage detector is composed of the detection flap and the limit switch. It has been installed on the chute side walls. To be mounted on the chute side wall. Sensitivity adjustable. The detecting force of flap can be adjusted in the range of 9.8 ~ 14.7N, which can detect small particles and big bulk materials.